Automated Direct Mail to U.S. and Canada Saves Time and Money

“We’ve definitely become more efficient. Step one was knowing the database was correct, making sure we’re getting this direct mail out to people. Step two for us will be that full analytical dive, to see what people are doing with that information.”

Tanya Steindl, Director of Marketing, Goodman Manufacturing

Tanya Steindl, Director of Marketing, Goodman Manufacturing

Goodman Manufacturing of Houston, Texas, is a division of Daiken Comfort Technologies. Daiken has been in operation for over 90 years across the world, servicing over 140 countries.

Goodman manufactures heating and air conditioning (HVAC) equipment. Their products include air conditioners, heat pumps, furnaces, and air handlers for homes and commercial buildings.

The company also supplies independent and co-distributor branches with aftermarket parts, supplies, and accessories sourced through a network of over one hundred vendors. Dealers use these items for installation and service, making Goodman Manufacturing a one-stop source of everything their dealers need to service their HVAC customers.

The Challenge: Sending Direct Mail to Both the U.S. and Canada Without Double the Work

Goodman’s marketing department connects with their dealers through email, direct mail, and point-of-sale materials. They take advantage of Hubspot and several internal databases to support their marketing strategies. The company markets to about 33,000 dealers in the US and Canada.

Monthly direct mail promotions typically highlight seasonal parts and other items via 6” x 9” postcards. The mailpieces also include information about the company’s loyalty programs or sales incentives, such as competitions for winning prizes like vacation trips.

Goodman’s print/mail service providers printed some Canadian mail in the US and shipped it to Canada. This process made timing the mailings more difficult as the mail had to clear customs before it could be delivered by Canada Post. Pandemic related staffing issues made the timing of delivery even more of a guessing game.

Manual Workflows Cause Problems: Creative Slows Down, Excel Files Aren’t Databases

The company used traditional print and mail service providers to manage the monthly postcard mailings. They found the process to be lengthy and manual to get artwork created, approved, tested, and for the mail to be produced according to Excel files sent to the service providers. Targeting was not as precise as the marketing department knew it needed to be.

The data used to power their campaigns had to be exported from source systems, stored and transferred to vendors in Microsoft Excel. As a result, Goodman didn’t really know how accurate their campaign data was. Without that understanding, it was hard to know whether they were wasting money on printing and mailing costs in both countries.

Direct Mail Campaign Analytics – No Easy Answer

Because the direct mail process was completely disconnected from marketing tech software, the analysis of the direct mail campaigns was slow, inefficient and incomplete. Without easy tools to measure deliverability and response, it was virtually impossible to get a true understanding of what was working and what wasn’t. The fact that they didn’t really know if their data was inaccurate and contained duplicates further complicated the analysis problem.

Tanya Steindl, Goodman’s Director of Marketing for Aftermarket Parts, felt a more hands-on approach would offer better opportunities for targeted messaging and improved direct mail effectiveness. A winning approach for Goodman would include support for their dealer network in the US and Canada.

The Solution: Automated Direct Mail for U.S. and Canadian Dealers via HubSpot® Integration

Goodman Manufacturing now uses Postalytics® for their direct mail marketing to dealers as well as internal HR communications with employees. With addresses in both the US and Canada, they were eager for Postalytics to add seamless support for Canadian mail to the platform. The company even paused their Canadian campaigns with their traditional print/mail service provider for a time, in anticipation of the Canadian offering from Postalytics.

We found it was much easier to create the graphics and then upload them ourselves. We could easily decide which customer list the postcards would go to and be able to get that target audience we were looking for. Before Postalytics, a third-party vendor managed this process on our behalf.”

Tanya Steindl

Director of Marketing

“Even a Lay Person Can Send Out a Postcard” – Postalytics Editor and Proofer Simplifies the Creative Process

With simple drag & drop functionality and a “bulletproof” digital proofing process, the Postalytics creative tools enable marketers to quickly deploy high quality, regulation compliant direct mail without needing to endlessly iterate with design and print and mail partners.

Personalized QR Codes Enable Easy Online Response

The Postalytics® platform includes a drag and drop QR code tool that gives recipients an easy way to hop online and respond to offers. The patented Postalytics® QR code solution is that each QR code that is printed and mailed is unique. When recipients receive the offer and scan the QR code, the Postalytics® system is tracking the unique visits, so that Goodman knows specifically who is responding to each offer.

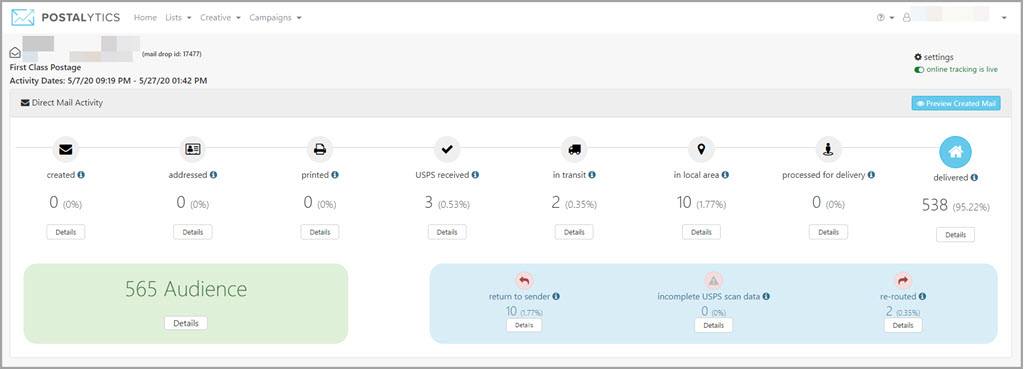

Dashboards Track Delivery and Response Metrics

All of the data about the campaign is tracked in a campaign dashboard, including:

- The printing status of each mailpiece

- The delivery status of each mailer (U.S. recipients)

- Invalid address data

- Data about each individual response

- The aggregate campaign totals for all of the above

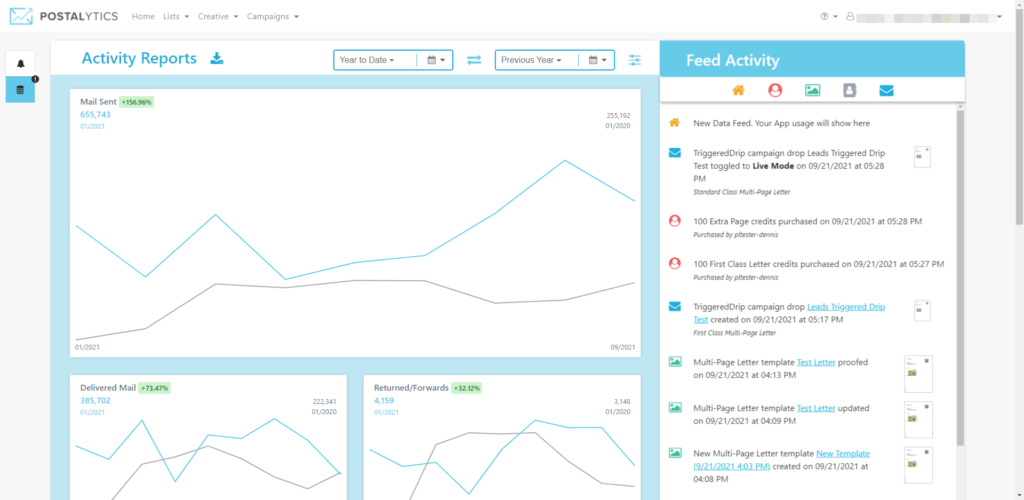

Account level views of all campaigns are easily analyzed in the home dashboard where cross campaign data can be filtered and analyzed to see the overall impact of the direct mail effort.

The Results: Fast, Efficient and Easily Analyzed Direct Mail Printed and Mailed in the U.S. and Canada.

Postalytics provided Ms. Steindl with the marketing control and flexibility she sought. The company now manages their own mailings to the dealer network, varying the content according to region. Postalytics tracks the results, displaying the activity in dashboards and reports.

Importantly, the issues with cross border campaigns and multiple vendors was solved when Postalytics began printing and mailing in Canada, using local Canadian print service providers and Canada Post Personalized Mail. The Postalytics software efficiently separates U.S. and Canadian addresses and routes mail to appropriate print partners without any need for manual effort.

Response Tracking Is Now a Reality

Goodman achieves tracking and follow-up with QR codes and personal URLs printed on the postcards the company sends to dealers who sell and install Daiken equipment to homeowners and commercial building managers.

“I love seeing the statistics when we use those personal QR Codes and we can actually see who’s going in and accessing the information”

Tanya Steindl, Director of Marketing, Goodman Manufacturing

Data Quality Issues Solved: Now Mailing to Good U.S. and Canadian Addresses

An unexpected benefit Goodman realized after switching to Postalytics for their automated direct mail to the U.S. and Canada was the feedback about the address quality the platform provides. This has allowed the marketing team to update their databases to ensure more accurate delivery in subsequent mailings.

Prior to implementing Postalytics, the company maintained their contact lists in Excel. They believed their files to be clean and correct. It wasn’t until they began using that data through Postalytics that they discovered duplicates, missing data, and undeliverable addresses in both the US and Canada.

“Now we know our list is around 33,000 names. We had believed it to be larger, and we were paying the third parties for more work than was necessary. Once we concentrated on actual people who were not duplicates or missing information, that really opened our eyes to how a clean list should look.”

Tanya Steindl

Self Service vs. Multiple Vendors & Costs

The self-service aspect of Postalytics was a big draw to the platform for Ms. Steindl and her marketing team. Seamless integration with HubSpot and the easy user interface were other attractive features.

“Even a lay person could actually send out a postcard if they needed to,” she noted. The Goodman Manufacturing graphics department creates the PDFs for the postcards. All the marketing department needs to do is drop them into the Postalytics platform.

Better Personalization and Segmentation Leads to Higher ROI

Cleaner data allows Goodman Manufacturing to employ more personalization and segmentation techniques with their direct mail, which generally improves response and conversion rates. The company’s database includes dealers from twenty different regions in two countries. The direct mail postcards carry messages that vary according to the geographic region of the recipient.

Since implementing Postalytics, Goodman Manufacturing has been able to use the statistical information provided by the platform to gauge the effectiveness of the postcards as they drive traffic to their e-commerce site. Soon they will expand their analysis to connect the postcard campaigns to actual orders placed as a result of the mailings.

Any ROI or campaign effectiveness calculations made by Goodman using their former direct mail strategy would have been flawed because of the unknown existence of duplicate and inaccurate data. With the Postalytics tools, the marketing team can finally precisely measure the results of their efforts.

“We’ve definitely become more efficient. Step one was knowing the database was correct, making sure we’re getting this direct mail out to people. Step two for us will be that full analytical dive, to see what people are doing with that information,” said Steindl.

What’s Next: Additional Offers, Finding New Customers & Canadian Mailings

The next phase for leveraging the power of Postalytics will be deploying triggered mail. The company initially concentrated on generating batch mailings but is well aware that the HubSpot Workflow tools can easily drive Postalytics “Triggered Drip Campaigns” by using the Postalytics/HubSpot integration.

One of the revolutionary parts of this new way to send direct mail to the U.S. and Canada is that marketers can mail constantly, one postcard and letter at a time, and not have to worry about meeting minimum mailing requirements. Ms. Steindl expects that, because of the way Postalytics works, her team will generate many more targeted mailings. They don’t have to mail to all 33,000 contacts every time.

“It’s cost-effective to do any size campaign at this point,” she said. They didn’t even explore the possibility of smaller mailings with their former print/mail supplier because it was too much work, but they knew their costs per piece would have risen with lower volume jobs.

Conclusion: Automated Direct Mail to U.S. and Canada Saves Time, Gives Better Analytics and Saves Money

Goodman Manufacturing had a working solution for communicating with their dealer network. Unfortunately, the process was more costly and inefficient than necessary. Working with a traditional print/mail service provider did not provide the level of segmentation and personalization that the company foresaw as a necessary component of their marketing strategy.

With some Canadian mail being produced in the US, predicting delivery dates for Canadian recipients was difficult, as the mail had to clear customs before being handed off to Canada Post.

By switching to Postalytics, the company uncovered data issues that were simultaneously adding to marketing costs and depressing the effectiveness of their marketing campaigns. Now, with a more hands-on approach, Goodman can monitor results more closely and make corrections and adjustments as necessary.

With the added support for Canadian addresses, Goodman can now send automated direct mail to the U.S. and Canada with previously unattainable efficiency while saving money and providing better analytics.